Your challenges > Ensuring predictive maintenance

AI for predictive maintenance

or predictive maintenance?

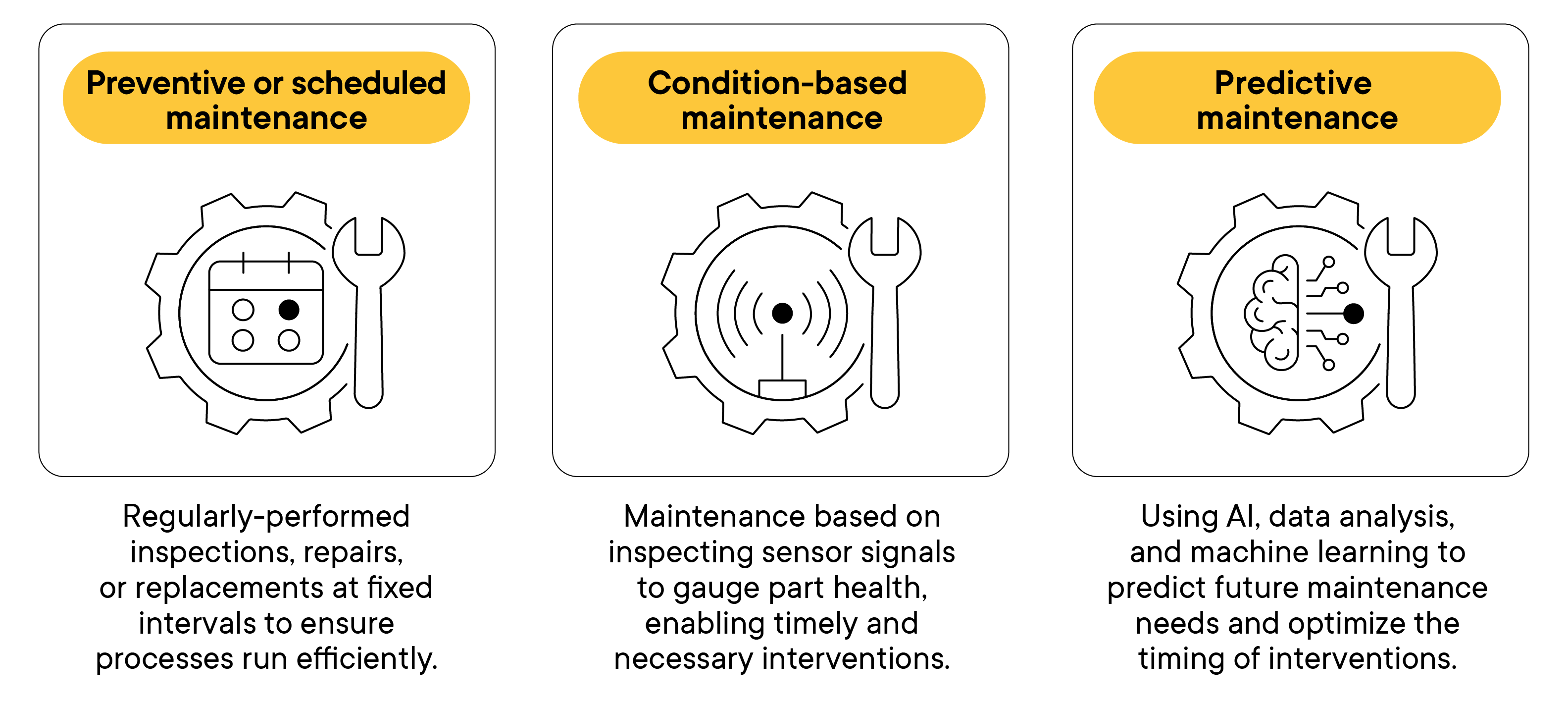

With predictive maintenance, you can further leverage this approach to optimize your maintenance operations, spare-parts inventory and technician schedules. Having a greater understanding of the remaining useful life of an asset can help you make important trade-off decisions between delaying maintenance and meeting production objectives.

A predictive maintenance strategy can reduce capital expenditures by extending asset lifetime, while increasing overall productivity. For example, it can increase equipment reliability and availability by proactively addressing operational wear and tear, while reducing unplanned and unnecessary maintenance.

Predictive maintenance solutions are beneficial for a wide range of equipment, from ‘simple’ assets like HVAC systems (heating, ventilation and air conditioning), to highly complex assets like aircrafts. Thanks to advancements in AI, big data analysis and advanced signal processing, predictive maintenance can provide benefits to a wide range of industries, including manufacturing, automotive, retail, hospitality and service, among others.

In partnership with AI practitioners and data scientists, IVADO Labs has developed robust methodologies for analyzing and flagging sensor signal anomalies in near-real time using a spectrum of techniques, from codifying rules leveraging expert technician knowledge to using deep neural networks within a single framework. This activates automated condition-based maintenance within your existing software stacks.

To further push the boundaries, we have developed diagnostic modules that can leverage technical documents, technician knowledge and statistical methods to automatically detect the most probable root cause(s) of degradation, fault or failure.

Our prognostics modules leverage predictive analytics as well as standard reliability methods to predict the future state and timing of potential faults of assets using both historical maintenance data and operational degradation to determine the remaining useful life of the component and system.